A new vacuum isn’t all Dyson has been working on, and Pickr’s European Correspondent Tristan Rayner got the goods on just how the world’s leader in vacuum technology tackles technological innovation.

Pickr attended the Dyson Cyclone V10 vacuum launch event in Paris, where Jake Dyson – son of Sir James – unveiled the all-new V10, a superb new vacuum with a new design that fixes a number of the small quibbles we had with the V6 and V8 range.

The launch itself was short, punchy, and mysterious. As we discussed in the unveiling piece earlier, this was a well kept secret, and Dyson thrives as fierce competitors in any space it takes on.

But while the launch was about a new vacuum that has the potential to do great thing in bigger environments, it was also the opportunity to see what makes Dyson tick. With over 4000 engineers working at the heart of the company, the projects it works on aren’t just led by marketing, but by ideas.

In fact, the V10 launch was a great chance to speak with some of those engineers, and Pickr was kindly granted some one-on-one time with Dyson’s Chief Research Officer, Mark Taylor, who despite having a masters and PhD and nearly 20 years with the company, looks barely a day over 25. Perhaps Dyson is also working on some kind of elixir of life?

Bad jokes aside, Mr Taylor and one of his engineering team members politely answered our questions and parried the usual ‘tell-us-all-your-secrets’ questions with good humour.

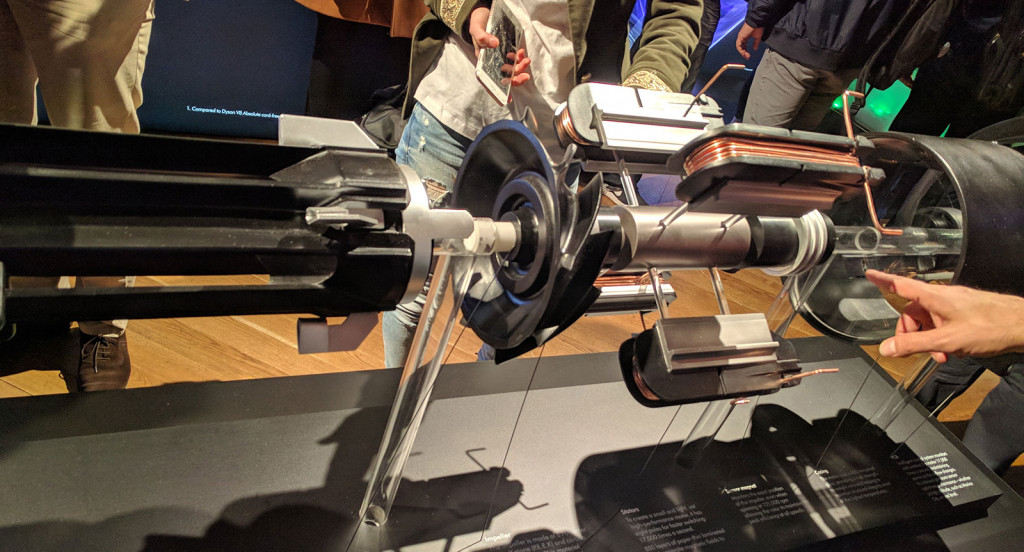

The exciting thing about Dyson is that its vacuums tell only some of the story. The crux of what Dyson has achieved in its new slim motor — which pumps out 525W at a much smaller size and mass than previous motors — is a hat-tip to the engineering prowess at the company.

Yes, it manages to boost suction by 20 percent with a new streamlined form-factor, but it’s what we’re going to see from Dyson down the road that goes from “Very Impressive Vacuums” to “Very Impressive Important Stuff”, like revolutionary batteries, and the potential for an electric vehicle.

Taylor heads the research arm of the New Products Innovation team within Dyson’s headquarters, which is home to what the company says are more than 80 “creative engineers” who develop concepts all the way through to working prototypes. New products start from an unusual beginning: prototyped without using any existing parts or even Dyson’s own technologies to create new projects.

That gets them thinking, that’s for sure.

Get them thinking, it did, and Taylor took quite a bit of time to explain the process behind building the all-new motors, something that took longer than you might expect, with no motors built at all until after 12 months of simulations and development.

“We don’t build a motor for 12 months from starting a project – everything is done in simulation,” explained Taylor.

“So the whole electromagnetic system – everything you see in the copper windings, and the electrical steel that sits underneath, and the [neodymium] magnet, is all done in simulation,” he said.

“It’s in an in-house simulation tool that’s completely proprietary, developed by us, in order for us to develop very rapidly, and iterate through various designs. That simulation matches within 1 to 2 percent of the physical motor, so it’s a very accurate tool.”

Affordability within technology

Taylor said one of the elements he’s most proud of from his team and throughout that of Dyson is that all the technology, the research, the development, and the application — all of these that Taylor says “are at aerospace level” — boils down to a motor that’s affordable for us to use in our households.

“There’s so many things I’m proud of with this motor, but to be able to design, develop and manufacture with these technologies in them, with a ceramic shaft, with neodymium magnets, with micron tolerances on the clearances between the propeller and the diffuser, to be able to do that at a cost that allows you to be placed in a domestic product… I mean these technologies are at aerospace level,” said Taylor.

Your next battery: solid-state

Taylor was willing to discuss Dyson’s controversial first-and-only outside acquisition, which was the purchase of Sakti3, a company working on new battery technology that was first spun out of the University of Michigan. This is solid-state battery (SSB) technology, where liquid fuels are replaced by solid fuels.

The controversy has come after initial fanfare about the acquisition and hopes for the technology that haven’t yet been seen. Dyson also relinquished Sakti3’s core battery patents, and the former CEO of Sakti3 has since left Dyson.

James Dyson did admit to Bloomberg last year that within the company, two separate teams were working on SSB tech, which may imply Sakti3 was simply beaten by other research. Certainly, Dyson’s chief research officer wasn’t playing down the significance of SSB in any meaningful way.

“Sakti3 is part of my team’s responsibility,” confirmed Taylor. “We’re very excited about the future of energy storage, [and] batteries are hugely important to us.

“We’re an enormous consumer of batteries, and batteries are pivotal to the performance of our machines, so we’re very active in developing new energy storage technologies. We think the future is SS, it’s the most energy dense way of storing and discharging electrical energy, we believe, so we’re very active in pursuing that technology and very hopeful for it,” he said.

“Battery chemistry [is an area that excites] – they’ve been have been held back for some time, they’re only improving at any incremental rates every year, and no big breakthrough in technology since John Goodenough,” said Taylor. “I’m really excited to be working on something that we believe will be able to revolutionise the world of batteries in the future.”

Taylor also confirmed the 2020 date as the year that we’ll see Dyson’s electric vehicle (EV) emerge from the shadowy depths of Malmesbury, where Dyson HQ is located, but couldn’t reveal anything more on this front except to acknowledge that artificial intelligence and machine learning are also exciting elements to Dyson’s products, with perhaps a wink to what their EV car might be capable of down the road.

It likely won’t replace your V10 vacuum, but it could perform like its namesakes, the V6, V8, or V10 for which the vacuums are named. Cars are obviously very different beasts than vacuums, but with Dyson working on the idea, we’re bound to see something intriguing, and with this development one of the hundreds being worked on at Dyson HQ, it won’t be long until you see something else from the minds inside Dyson’s labs very soon.